Our Business

A trusted partner where you need us across the globe

Vallourec is a leading provider of high-quality tubular solutions for the energy sector and various other applications, including some of the most demanding ones.

Our products are used in extreme conditions, ranging from oil and gas wells to next-generation power plants, in ambitious architectural projects and high-performance mechanical equipment.

Adapted to the challenges of the 21st century, our innovative solutions are designed for three primary markets: oil and gas, low-carbon energy, and industrial applications.

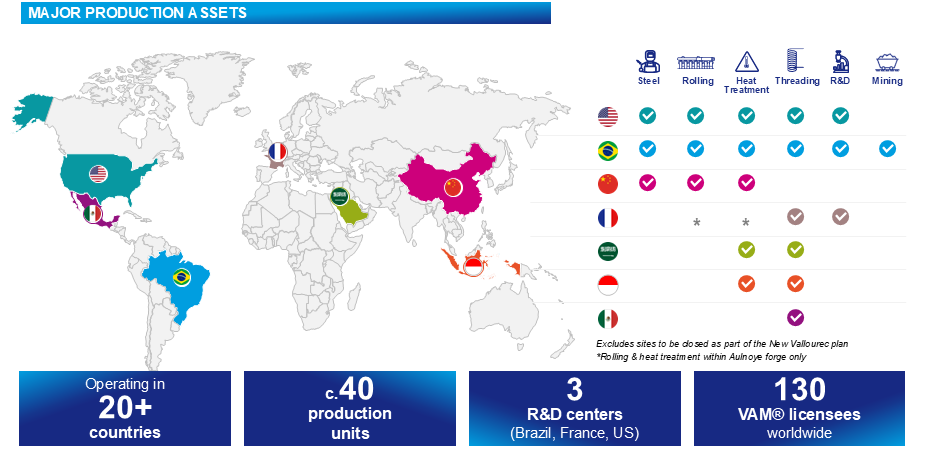

We’re backed by a strong international presence and our major production hubs are found in the following countries across the world.

Our Markets

Oil Country Tubular Goods (OCTG)

Vallourec is North America’s leading producer of seamless tubular, line pipe, and coupling stock for the oil and gas markets.

Our products are 100% Made in America. We are a company proud to make steel in Youngstown, Ohio.

Our mills in the US offer premium threading to our pipes to the tightest tolerances this industry demands.

Our pipes play a crucial role in industries like power plants and refineries. We also contribute to civil construction projects such as bridges and buildings, agriculture, and even automotive and defense. Our products support a diverse range of industries that extend far beyond just oil and gas.

Vallourec North America

Service Operations

Service Operations is home to multiple premium threading lines for VAM® premium connections in Houston, Texas.

- on-site product development

- qualification tests

- field and technical services

Vallourec Tube-Alloy is located in Houston, Texas and Houma, Louisiana, and provides downhole premium accessories, including THERMOCASE® Vacuum Insulated Tubing (VIT).

Mass Production North

Our steel and pipe-making operations are based in Youngstown, Ohio where we have a long legacy and have invested in a new state-of-the-art steel mill.

- Electric arc furnace (EAF) steelmaking technology

- pipe rolling

- heat treatment

- inspection

- finishing

- API threading

- semi-premium and premium threading

Mass Production South

The Houston, Texas, operations provides provides precise temperature control and water quenching, allowing the production of high-yield strength OCTG and coupling stock required for today’s critical environments.

- heat treatment

- straightening and hot sizing

- finishing

- hydrostatic pressure testing

- premium threading services

- inspection

- 8D collapse testing

- semi-premium

- API threading

The Mass Production facility in Muskogee, Oklahoma, specializes in producing and inspecting high-performance, proprietary, and custom casing and coupling stock.

- heat treatment

- straightening and hot sizing

- finishing

- hydrostatic pressure testing

- premium threading services